Innovative solutions for sustainable Environment

Enquiries or Questions?

—–> Reach Us Now

Our Product Catalogue

—–> Click here to see the range

Sewage Treatment Plant

Effluent Treatment Plant

Effluent Treatment Plant or ETP is one type of waste water treatment method which is particularly designed to purify industrial waste water for its reuse and its aim is to release safe water to environment from the harmful effect caused by the effluent. Characteristic of wastewater must be taken into consideration in terms of physical, chemical and biological characteristic.

Trade Effluent is generated in many manufacturing industries like food, textile, tanneries, pharmaceuticals, paper and chemicals etc. The effluent bears large amounts of organic matter and hence the raw effluent cannot be discharged without proper treatment. Discharging the effluent may cause polluting the existing water bodies resulting depletion of DO and will distress the environment. Hence, in order to meet the recommended standards of quality of the effluent, it is necessary to treat the effluent before it is finally disposed off. This treatment facility provides for removal of major pollutants from the effluent.

There are three main stages of the wastewater treatment process, suitably known as preliminary treatment, primary, secondary and tertiary water treatment. In some applications, more advanced treatment is required, known as quaternary water treatment.

Preliminary treatment is the process of removal of materials that inhibit the biological processes in secondary treatment.

Primary treatment is the second step in wastewater treatment. It allows for the physical separation of solids, oil & greases and grits from the effluent. The screened wastewater flows into a primary settling tank where it is held for several hours permitting solid particles to settle to the bottom of the tank and oils and greases to float to the top.

Biological treatment process that eliminates dissolved organic material from effluent. The partially treated wastewater from the settling tank flows by gravity into an aeration tank. Mixing of water to solids containing that use oxygen to consume the remaining organic matter in the wastewater as their food supply and the liquid mixture is sent to the final clarifier. In clarifier, solids settle out to the bottom where some of the material is sent to the solids handling process and some is recycled back to top-up the population of micro-organisms in the aeration tank to treat incoming wastewater.

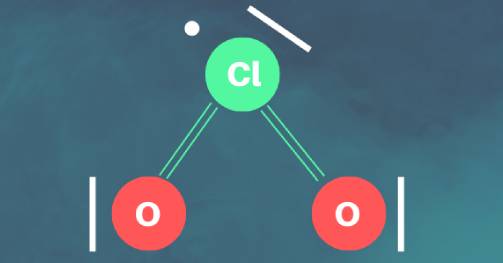

Treated water is disinfected by chlorination and then it is sent out for wastewater reuse activities or for discharging in any water stream or onland for irrigation.

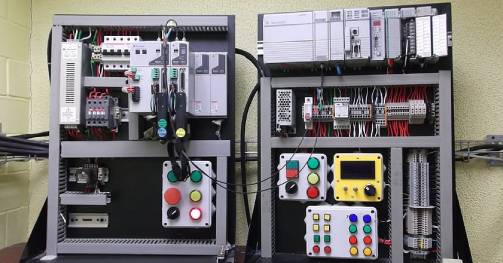

We optimize the pre-treatment, primary treatment, secondary treatment and tertiary treatment system involved in ETP. This is achieved by analyzing the physical, chemical and biological impurities present in raw effluent from its source.

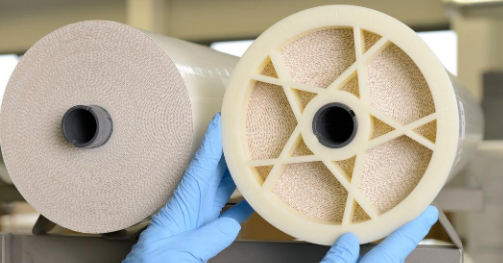

We practice several innovative technologies like Membrane bio reactor, Surface-aerated basins, aerated filters, activated sludge process, extended aeration etc in our ETP systems. We ensure that our plants are efficient, reliable and cost effective and we ensure that required reduction of BOD, COD, TOC levels are achieved in our treatment plants.